Casinos in Schleswig-Holstein

Object

- Casino Lübeck

- Casino Schenefeld

Hardware

- DALI via Wago SPS

- DMX (CueCore)

- Cloud DCM1 Digital Zone Mixer

- HDMI Matrix Switch for controlling video

- Shading

- Climate sensors

Symcon-Products

- Symcon in a VM

- Function blocks for scene control

- Symcon Visualization

- Additional development for special hardware

What was it about?

The project involved the modernization of two casinos in Schleswig-Holstein into modern "club casinos" that combine classic gaming with events and entertainment. The focus was on the implementation of cross-system building automation. Ventilation, shading, lighting and the control of audio and video systems were to be operable by employees using tablets via scenes. No visible switches were to be installed in the rooms in order to reserve all control for the employees. Regular operation should therefore be fully automated.

Which systems were used?

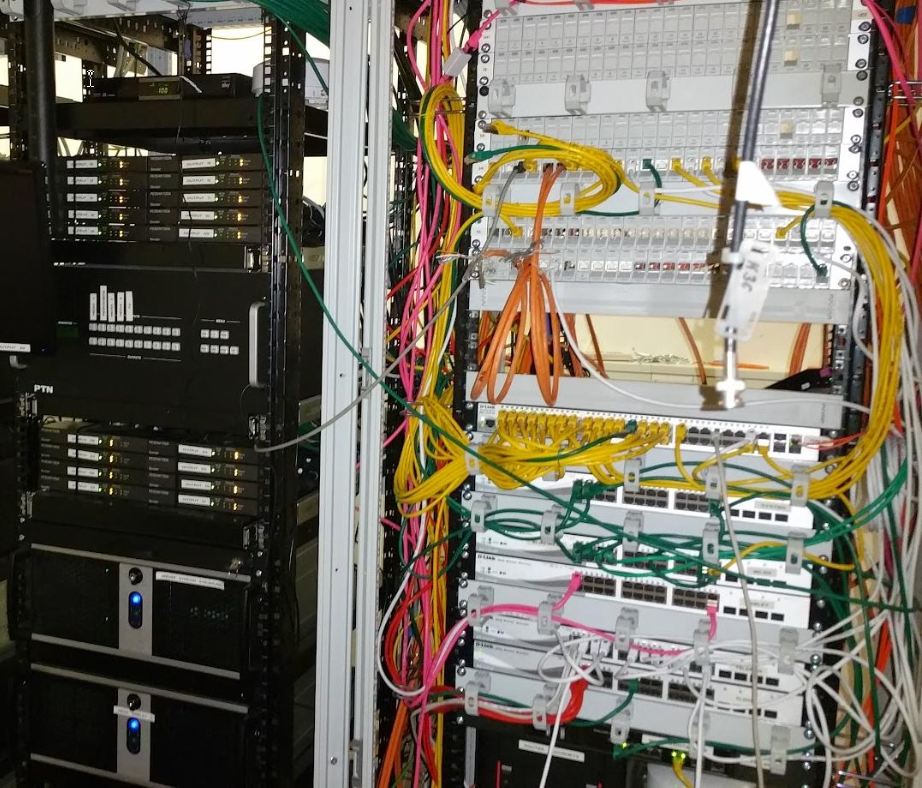

DALI was connected via a Wago controller to control the lighting. DMX is used for the event-specific lighting technology that is used for events. The various lighting scenes are started automatically at specific times and can be overridden by employees. Employees also have the option of selecting different music sources in the respective rooms. For this purpose, the media technician recommended the Cloud DCM1, for which there was previously no integration in Symcon and which was therefore specially developed. A Symcon integration was also developed for the control of around 20 monitors using an HDMI matrix switch in order to switch intelligently between food/drink offerings or game stands.

How was Symcon used?

The main task of Symcon was to connect the devices from different manufacturers and use modules and function blocks to implement automatic control without manual input. Thanks to Symcon's flexibility, systems that were not yet supported, such as audio and video control, could be easily integrated. In order to tailor access to different components and functionalities for different employees, custom visualizations were created that clearly break down the required range of functions.

Conclusion

During the conversion, Symcon was already installed and pre-programmed in the technical rooms. This allowed the final connections and automations to be made via remote maintenance. Thanks to the level of automation provided, no manual control by employees is necessary during regular operation.

| Project Link | To the homepage |

| Integrator | Symcon GmbH |

| Location | 23554 Lübeck |

| support@symcon.de | |

| Phone | +49 451 30 500 511 |