Ford plant in Saarlouis

Object

- Automobile manufacturing plant

- Commissioning in 1970

- Up to 4700 employees

Hardware

- Rechenzentrum

- WAGO SPS

- Diverse Stromzähle

Symcon-Products

- Symcon Enterprise in a data center

- IPSView

- Logging/Charts

- Leak detection

- Symcon Enterprise Support On-Site

What was it about?

In general terms, the aim was to save energy and to record and identify possible leaks or unnecessary energy consumption. This also involved measuring temperatures, detecting compressed air leaks and recording ink levels in the machines, for example. In other words, comprehensive energy monitoring. Although data had been recorded, it was poorly visualized and had no context.

Process control was not to be mapped, even if Ford later implemented it independently to some extent.

Which systems were used?

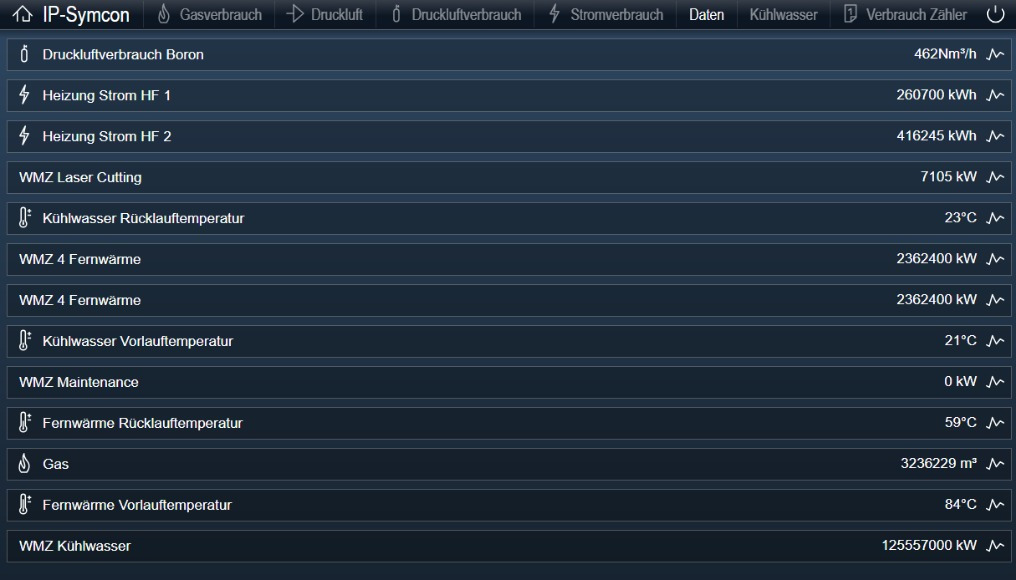

The infrastructure via tens of WAGO PLCs was in place. The network via LAN and data center was also established. This meant that the raw data was already available.

What were the challenges

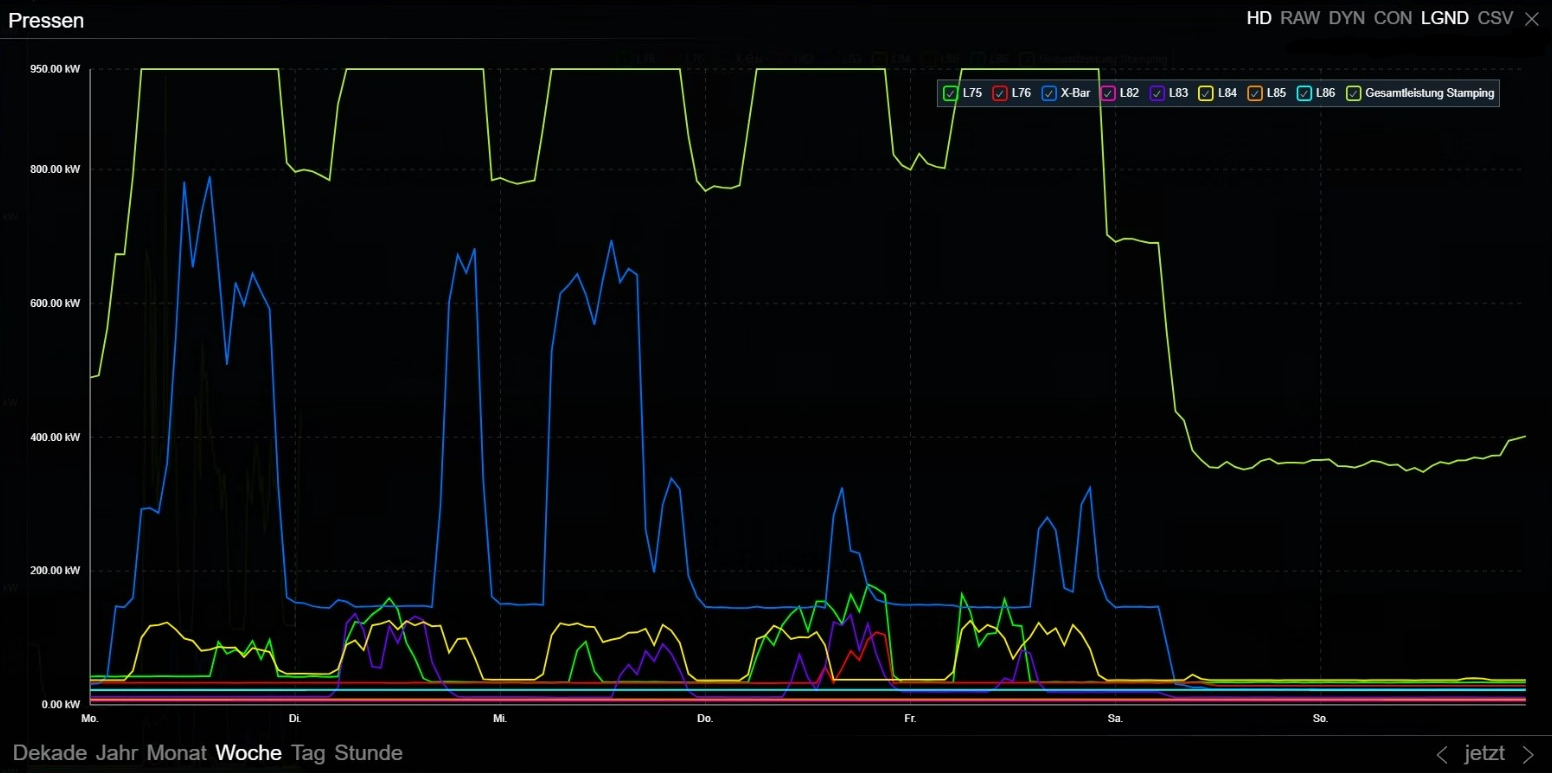

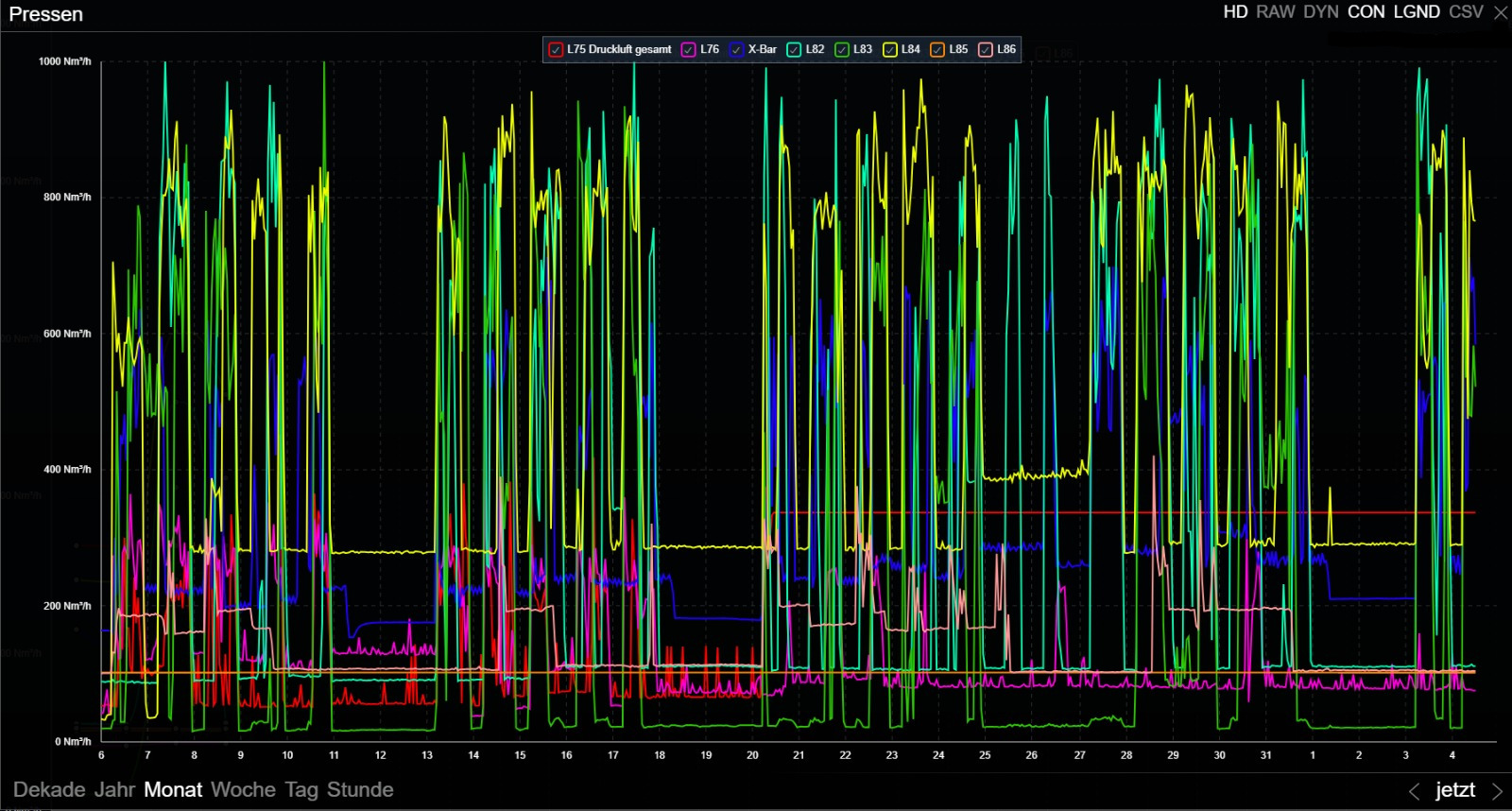

The sheer size of the plant and its distribution across several halls posed a particular challenge. Initially, only the press shop was recorded in terms of energy technology as a pilot project. Later, the paint shop, final assembly and administration buildings were added.

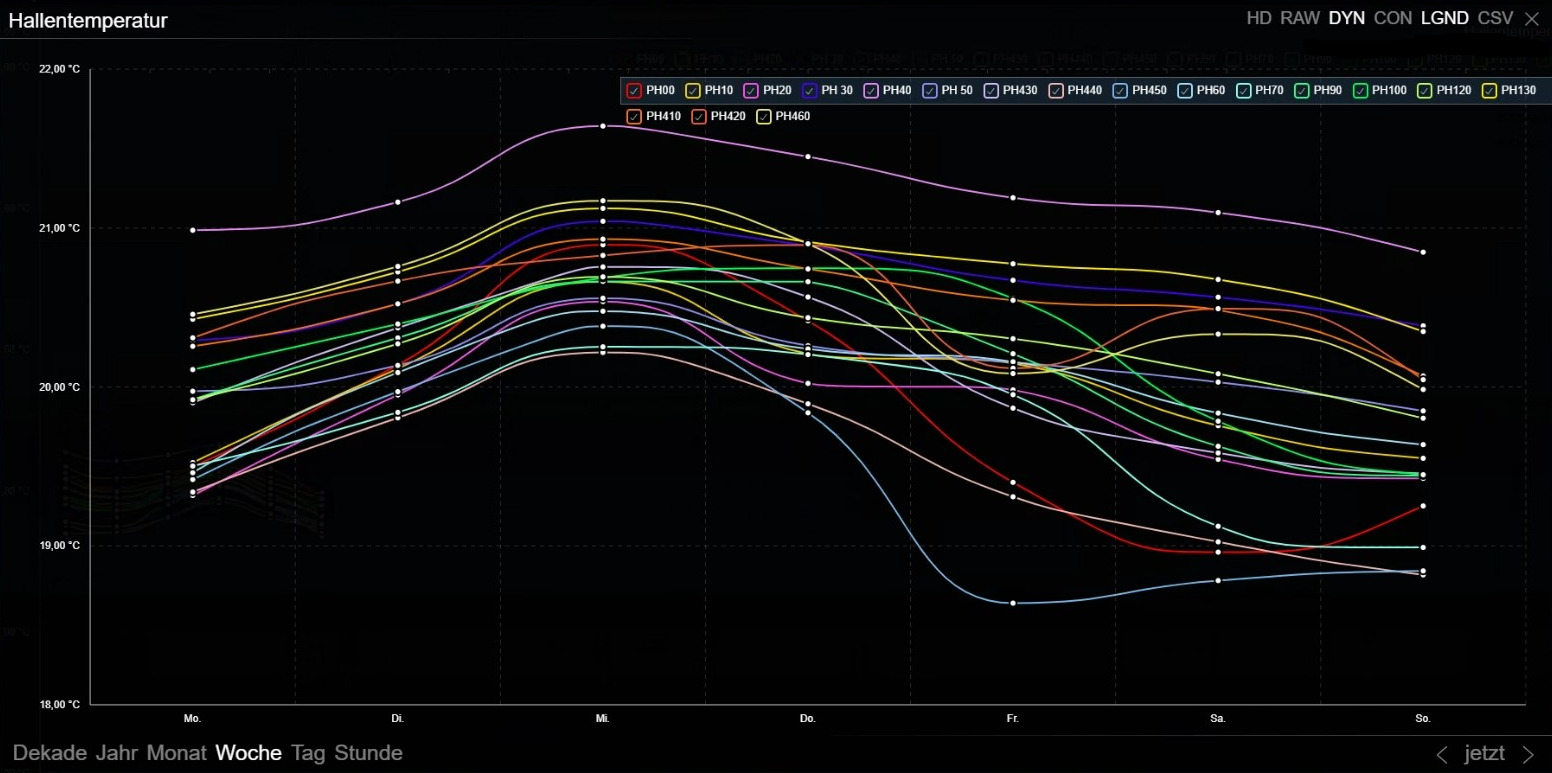

In addition, the existing raw data was not monitored live and had no warning capability for unusual behavior (e.g. leakage detection) or a door was left open unnoticed for a longer period of time, causing heated air to escape or too warm air to flow in during the summer.

How was Symcon used?

In the beginning, the first goal was to record the energy consumption of the pressing plant. Above all, the temperature and the associated heating was a major factor, as was the production of compressed air. All WAGO PLCs in the press shop were integrated for this purpose. These were connected to the ventilation system and heating system. Hall door statuses were also recorded and logged.

Symcon was used in conjunction with IPSView. This enabled the status of the doors and temperature curves to be visualized. Leaks in the compressed air circuit were detected by evaluating the pressure and operating states of machines.

| Project Link | Project Homepage |

| Integrator | Symcon GmbH |

| Location | 23554 Lübeck |

| support@symcon.de | |

| Phone | +49 451 30 500 511 |

Conclusion

Thanks to real-time monitoring and logging, abnormal behavior and conditions could be detected much more quickly. This meant that the responsible teams could be deployed or informed more quickly.

In the course of the Symcon 2021 event, Ford reported to us that they had already been able to save considerable energy costs in the meantime in a barely optimized process flow. This only happened by viewing logged data and the newly acquired real-time response. In addition, the central monitoring of the filling levels of painting systems has led to a far better process flow.

After a few years, the consumption of compressed air alone was reduced by over 70%. In the wake of Symcon's success, this was approved as an energy monitoring system for all Ford plants worldwide.